|

Preface: I actually started turning these columns

before turing the center column, and this was before I started

documenting my work. However, I didn't finish these columns until

later. That is why I wrote about them after the center column, and also

why there are fewer pictures.

Wood Preparation

For the eight fluted columns around the

outside of the

pedestal, I wanted to make sure that the wood grain and color was

consistent,

so I hand picked a mahogany plank large enough to get all of the

columns

from the

same board. I started out by planing a 12-foot long by 14-inch wide by

2-1/2-inch thick plank of mahogany. I think it weighed at least 150

pounds. After surfacing

the plank, I cut it into more manageable

segments and jointed and ripped them into 4-1/2 inch wide pieces for

glue-up (3

rips per segment).

This plank of wood was more than I needed

for the columns, but because two of the resulting pieces had

visible structural

defects in the grain (cleaving grain), I decided to cut the entire

plank into

turning blanks, resulting in 5-more pieces than I actually needed. This

would

give me enough material to make 2-1/2 extra columns. Instead of

throwing away

the two flawed pieces, I decided to use them as a

“machine-setup” column. In other words, this was a sacrificial column

that I

could ruin in the process of setting up subsequent machining, but it

would

never be used beyond that. The other pieces also gave me one extra good

column

as a spare just in case something went wrong, which of course, it

did!

I

got into quite a “groove” turning these columns, and

the round blanks were coming out extremely accurate and consistent.

However,

since this is before I started taking pictures, this topic is rather

dull and

boring, so I will skip ahead a couple of steps and dive into the

fluting task.

This is when I began documenting my progress.

|

I forgot that I had this picture, but it is the only one I

have of the unfluted columns. I set all of the columns out on the floor

just to get an idea of the scale and design of the pieces to make sure

that what I was visualizing during the design was how the actual parts

would look.

|

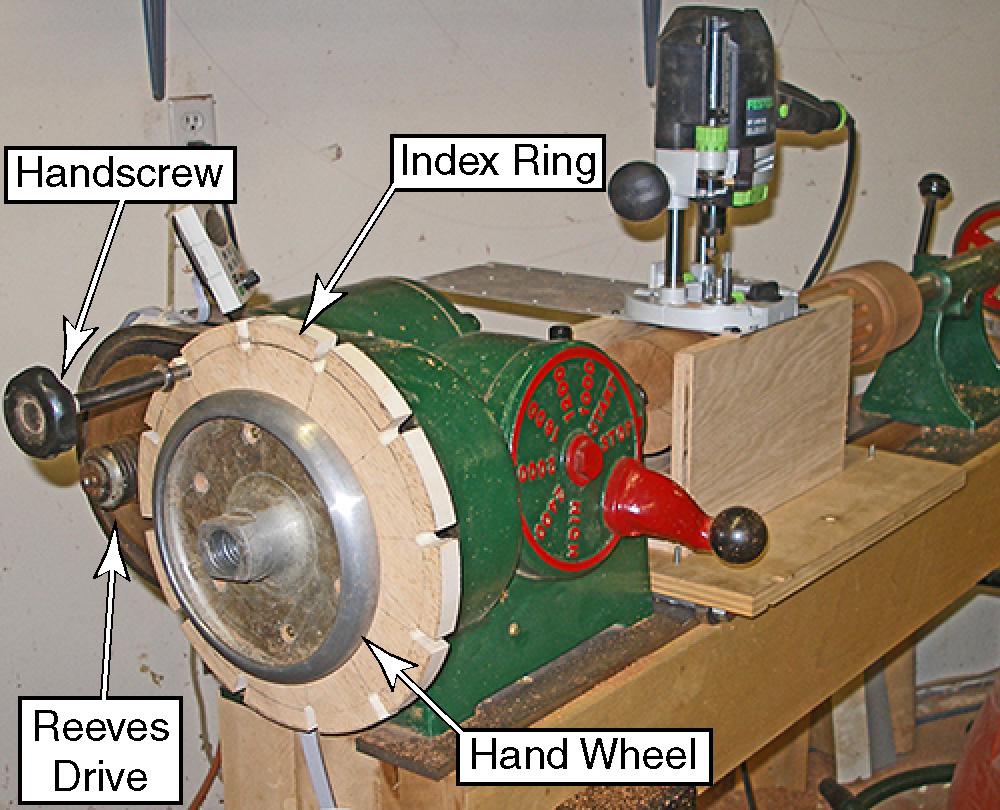

Indexing Ring

I knew that the best way to flute the

columns was to keep

them mounted on the lathe and run the router on rails over them,

but my Oliver

lathe was not easily adaptable for indexing the turning every 30

degrees. So I

decided to create a sled for the shaper. This didn’t work. The first

column went

OK, but the second column went south. Since I had only one spare column

and

couldn’t afford to ruin another one, I decided to take the time to make

a

router carriage for the lathe.

It took a while to figure out how I could

make an accurate

indexing ring without altering my vintage Oliver lathe. I removed the

bell

housing from the reeves drive, inverted the hand wheel, and screwed the

indexing ring onto the back of the hand wheel. I slotted the indexing

ring so I

could run a bolt through the ring and into the original mounting hole

for the

bell housing. I later discovered that the big handscrew from my

shaper’s

fence fit the bolt hole. This made changing the index a lot easier. It

doesn't look very pretty, but it sure worked well.

|

|

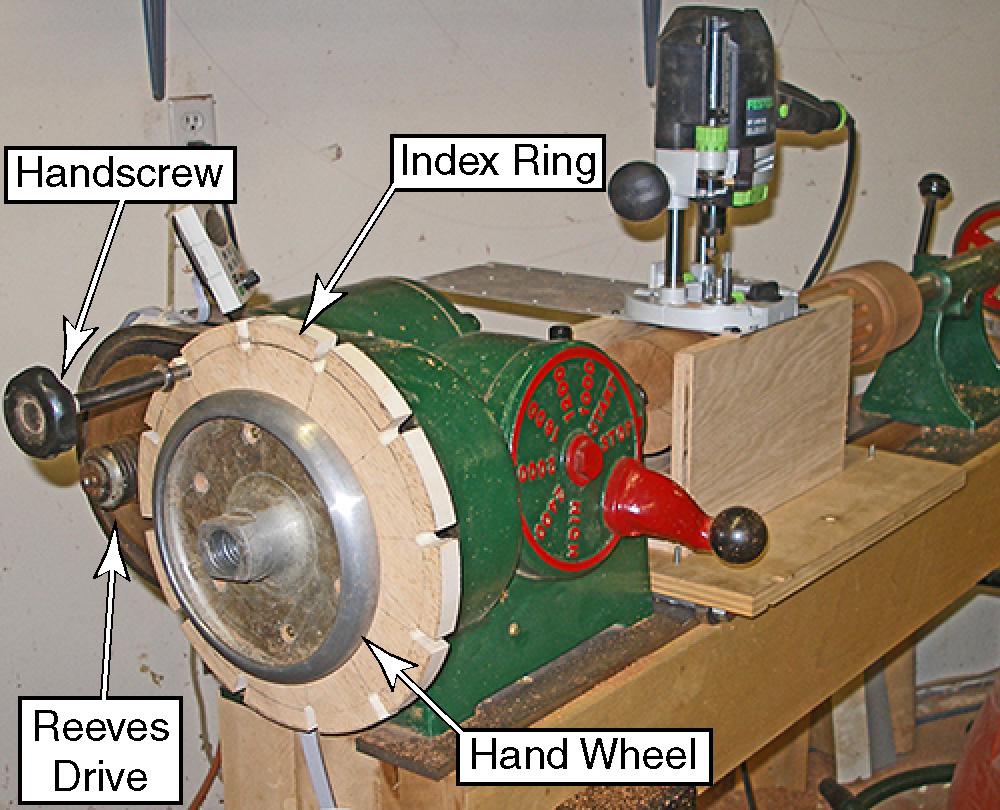

Router Carriage

The router carriage for the lathe was

actually easy. I already had

the base of the carriage built years ago to hold my drillpress to make

a large set of hollow

spiral columns.

It uses bearings as wheels and is captive between the steel rails of

the lathe

bed. I mounted my Festool OF1400 router to an aluminum sheet and

mounted that

to the carriage.

I positioned the router so the carriage

would hit the lathe's headstock at the top of the flutes. To control

the bottom position of the flutes, I used the tailstock as an

adjustable stop. I could change the position of the end of the flutes

by increasing or decreasing the extension of the live center.

To flute each column, I locked the indexing

ring into one

slot. I then moved the carriage toward the headstock and plunged the

router

down

into the column. I then rolled the carriage to the side until it hit

the base

of the tailstock. With each

single flute complete, I had to remove the hand-screw, rotate the index

ring to the

next slot, and repeat this 12 times for each column. It was mind

numbing

redundant work, but with this setup, it was error-proof.

|

|