Climb-Cutting Versus

Chip-Cutting

By Rick Christopherson

So you've built this beautiful jewelry box. Now comes the moment

to add the finishing touches, like routing a nice decorative profile

around the top. ----Craaaack!----There goes a 3 inch long chip from

the edge, destroying many hours of work.

You can prevent tearout when using a router; its just a matter of

the feed direction. There are two choices when it comes to the feed

direction with a router: Climb-Cutting, and Push-Cutting.

Push-Cutting

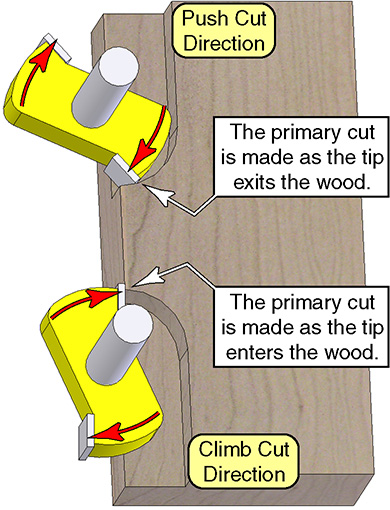

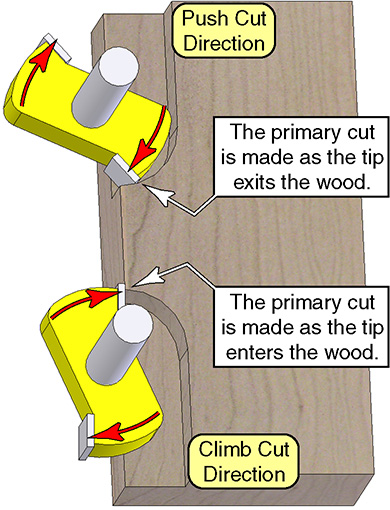

Push-cutting refers to the feed direction of your workpiece

which opposes the rotation of the cutter head.  Push-cutting is

typically considered the "normal" feed direction because it is

safest: the router doesn't want to runaway on you. However, push-cutting has the greater tendency for tearout. As the

carbide tip strikes the wood, the path of the cutter travel is

out of the wood, and the deepest cut is in-line with

the grain. The result, is that the carbide is cutting the wood on the

Exit Stroke.

Push-cutting is

typically considered the "normal" feed direction because it is

safest: the router doesn't want to runaway on you. However, push-cutting has the greater tendency for tearout. As the

carbide tip strikes the wood, the path of the cutter travel is

out of the wood, and the deepest cut is in-line with

the grain. The result, is that the carbide is cutting the wood on the

Exit Stroke.

The drawback to this direction, is that it tends to tearout the

wood more, because the wood fibers will easily split lengthwise. As

the cutter catches each fiber, it tends to pull it away from the main

body of wood.

At the same time as the wood fibers are being pulled away

from each other, the cutter head is being pulled deeper into

the main body of wood. If the cutter has a bearing, this direction of

cut will have the tendency to force the router to ride into the

bearing (or fence) more.

In the push-cut direction, chatter is reduced because the router

bit is applying a steady inward force to the cut.

Climb-Cutting

Climb-Cutting is when the feed direction of the workpiece is the same

as the rotation of the cutter. The term climb-cut comes from

the fact that the router bit has the tendency to climb into the cut,

or if you can visualize it, "walk" its way down a board. This is what

makes climb-cutting so dangerous: the router bit has more control

over the feed rate than you do, and if you don't carefully control

it, the router or workpiece will take off on you.

Putting aside the dangers, the primary benefit to climb-cutting is

that there is less, or even zero tearout. This is because the carbide

strikes the wood with the deepest portion of the cut cross-grained

and into the wood. That is to say, the carbide is

cutting the wood on the Entry Stroke, which is compressing

the wood fibers versus pulling them apart.

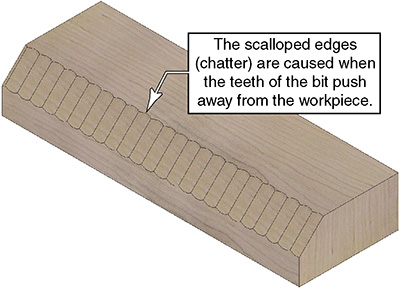

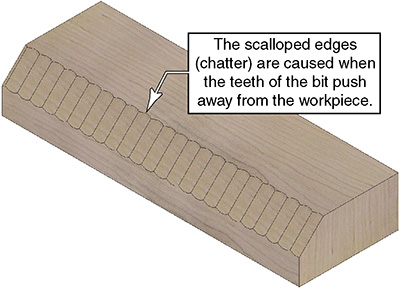

Aside from wanting to climb its way down the board, another side

effect of climb-cutting is that the bit will be pushed away from the

wood. As the carbide enters the wood, the force of the tip striking

the wood surface tends to push the wood away from the bit. This has

two effects. First off, the cut will almost never be full depth on

the first pass of the cut. Secondly, since the cutter tips keep

pushing the bit away from the wood twice per bit revolution, you end

up with more chatter. This chatter is caused from the cutter bouncing

in and out as each knife strikes the wood.

Applying These Concepts

The First Pass

To reduce the tearout while routing, I make the first pass in the

climb-cut direction. To prevent the router from running away on me, I

make this pass rather light. Since the router bit is naturally pushed

away from the wood during climb-cutting, making a light pass is

automatic: I just don't apply as much inward force.

Furthermore, I use friction to control the feed rate, not

muscle. When you try to muscle the router to control the feed rate,

then you are relying on your reaction time to compensate for

changes in the feed rate. You can never react fast enough.

With friction, there is no reaction time needed, there is just a

constant force opposing the climb. While holding the router's handle,

the butt of my fist is pressed down firmly onto the surface of the

wood. When starting or stopping a cut, I firmly plant my fist on the

wood, and use the other hand to rotate into or out of the cut. This

gives me very good speed control over a short distance. As I move

down a long board, I just drag the edge of my fist (or even forearm)

down the wood.

I won't climb-cut with a router bit that is too large to safely

control. For larger bits that aren't too large, or anytime I don't

feel completely in control, then I will plant my fist in one spot and

make short, shallow strokes by rotating the router into the cut with

the other hand.

Cleanup Pass

After the first pass, I make a cleanup pass in the chip-cut

direction. This ensures that the route went full depth, and also

removes the chatter marks left by the climb-cut. Because the majority

of the material has already been removed, the direction that the

carbide tips strike the wood is nearly parallel to the grain, and

therefore, no chipping occurs. I also make this last pass with a

fairly fast feed rate to ensure that there is no burning.

Using a Router in a Table When hand feeding stock

through the shaper or table mounted router, don't even consider

climb-cutting: It's a good way to lose a finger. You have no way

to control the feed rate when you are moving the workpiece on a

table. While you may think you can stop the piece from grabbing and

taking off, you can't.

If you have a power feeder for the shaper/router table, then

climb-cutting is feasible, but still very dangerous. My shaper is

setup to do 95% climb-cutting, but I have a rather large power feeder

(shown in the adjacent photo). The small "baby" power feeders, may

not provide enough workpiece control for climb-cutting. Regardless

of your feeder size, this is still dangerous. Never allow anyone to

stand in the outfeed path.

Most of the time, I do not need a cleanup pass on the shaper, but

the smaller the feeder, the more important this will be. If a cleanup

pass is needed, you can either change the feed direction to chip-cut,

or leave it in the climb-cut. I usually stay in the climb-cut

direction.

Conclusion Don't perform any operation just

because someone else has done it without problems. Regardless what

you do, or how you do it, routers and shapers are dangerous tools.

You must operate them with 100% confidence, but never let your

respect for them drop either. Operate the tool with respect.

Never, never, operate a tool when you have a "fear" of the tool, or

operation. There is a thin line between respect, and fear. Don't

cross that line, or you will be injured.

If you found this article from a search engine, and would like to

jump to the Waterfront Woods Home page, click on the image below.

Email

Rick Christopherson

Email

Rick Christopherson

Push-cutting is

typically considered the "normal" feed direction because it is

safest: the router doesn't want to runaway on you. However, push-cutting has the greater tendency for tearout. As the

carbide tip strikes the wood, the path of the cutter travel is

out of the wood, and the deepest cut is in-line with

the grain. The result, is that the carbide is cutting the wood on the

Exit Stroke.

Push-cutting is

typically considered the "normal" feed direction because it is

safest: the router doesn't want to runaway on you. However, push-cutting has the greater tendency for tearout. As the

carbide tip strikes the wood, the path of the cutter travel is

out of the wood, and the deepest cut is in-line with

the grain. The result, is that the carbide is cutting the wood on the

Exit Stroke.